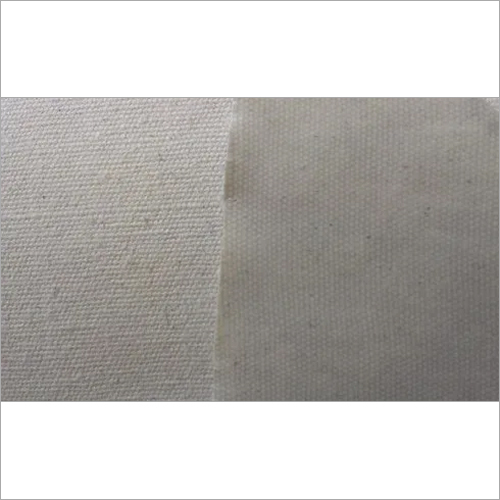

LDPE Coated Fabric

Price 35 INR/ Meter

LDPE Coated Fabric Specification

- Width

- Up to 72 inches or as specified

- Weave Style

- Plain Weave

- Pattern Type

- Single color, can be customized

- Water Proof

- Yes

- Fabric Material

- Woven Fabric coated with LDPE

- Application

- Outdoor, Industrial, Agricultural, Transportation

- Stretch Type

- Low Stretch

- Material

- LDPE Coated Fabric

- Texture

- Smooth

- Style

- Plain/Coated

- Yarn Count

- Varies as per base fabric

- Density

- 550 Gram per cubic centimeter(g/cm3)

- Weight

- As per specification (e.g., 200 GSM)

- Length

- As per requirement or standard rolls

- Strength

- High Tensile and Tear Strength

- Use

- Tarpaulins, Covers, Tents, Packaging, Agriculture, Construction

- Attributes

- Durable, Tear Resistant, Lightweight, Flexible

- Color

- Multiple colors available

- Pattern

- Plain

- Fabric Type

- Coated Fabric

- Size

- Customizable

- Customization

- Available for GSM, Color, Size, and Finish

- Standard Packaging

- Roll or Bale Packaged

- Chemical Resistance

- Good

- Temperature Resistance

- -30°C to +70°C

- Surface Treatment

- Corona Treated Option

- Shrinkage

- Minimal

- UV Resistance

- Available as per request

- Base Fabric

- HDPE Woven Fabric

- Coating Thickness

- 80 to 150 microns

- Fire Retardant Property

- Available on request

- Eco-Friendly

- Recyclable Material

- Lamination

- Single Side/Double Side LDPE Coating

LDPE Coated Fabric Trade Information

- Minimum Order Quantity

- 500 Meters

- Supply Ability

- 20000 Meters Per Week

- Delivery Time

- 1-7 Days

- Main Domestic Market

- All India

About LDPE Coated Fabric

We offer a broad array of supreme quality LDPE Coated Fabric that finds wide application in different industries. The offered fabric is woven with the utilization of premium quality threads or yarn and the latest techniques at our well-established weaving unit. Offered fabric is majorly used to cover vessel for shipping or storing dry and wet chemicals, paste or food products. The provided fabric have high tear resistance and thus, appreciated and preferable in the ongoing market. Moreover, this LDPE Coated Fabric can be availed in diverse specifications within committed time frame.

Features:

- High strength

- Durability

- Waterproof

- Tear resistance

Versatile and Customizable Coated Fabric

LDPE coated fabric offers remarkable adaptability across various sectors, including agriculture, construction, and packaging. With customizable options for thickness, width, color, and GSM, each order can be tailored to precise requirements. Its smooth texture and plain weave enhance visual appeal while maintaining robust protection against harsh elements. The fabric is available with up to 72-inch width and supplied in rolls or bales, ensuring convenience and ease of handling.

Durability and High Performance

The HDPE base lends exceptional tensile and tear strength, making the LDPE coated fabric lightweight yet sturdy. It boasts minimal shrinkage, low stretch, and high flexibility, ensuring reliable performance in outdoor and industrial environments. UV resistance, fire retardancy, and chemical resilience can be included as per request, further improving its suitability for challenging applications. Its waterproof design provides consistent protection in varied climates.

FAQs of LDPE Coated Fabric:

Q: How is LDPE Coated Fabric manufactured and what makes it unique?

A: LDPE Coated Fabric is produced by bonding a high-density HDPE woven base with a layer of LDPE coating, typically 80 to 150 microns thick. The process may include corona treatment and single or double lamination, resulting in a strong, smooth-textured, and flexible material distinguished by its high durability and adaptability.Q: Where can LDPE Coated Fabric be used?

A: This fabric is widely utilized in industries like agriculture for covering crops, construction for outdoor shelters and weatherproofing, transportation for tarpaulins, and packaging for robust wraps. Its versatility extends to tents and industrial covers, functioning reliably in both indoor and outdoor settings.Q: What benefits does the LDPE Coated Fabric offer over conventional materials?

A: LDPE Coated Fabric provides high tensile and tear strength, lightweight flexibility, minimal shrinkage, and good chemical resistance. It is waterproof, recyclable, and can include UV resistance and fire retardancy, making it superior for durability and environmental sustainability compared to many alternatives.Q: Can the LDPE Coated Fabric be customized for different specifications?

A: Yes, customization is available for the fabrics GSM, color, size, finish, and lamination type. Clients can select options such as corona treatment, UV resistance, and fire retardant properties, ensuring the product precisely matches their application requirements.Q: What is the process for ordering LDPE Coated Fabric with custom attributes?

A: Clients can specify their desired GSM, color, width (up to 72 inches), length, and finish. Packaging is offered in rolls or bales for easy handling, and additional features like UV and fire resistance can be incorporated upon request. Orders are fulfilled by manufacturers and exporters based in India, supporting a wide range of client needs globally.Q: How does the LDPE Coating enhance the base HDPE woven fabric?

A: The LDPE coating provides a waterproof barrier, enhances smoothness, and improves resistance to chemicals, UV light, and physical stress. This synergy results in minimal shrinkage, low stretch, and long-term durability even in challenging outdoor or industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laminated Canvas Category

Jute Laminated Canvas Fabric

Price 35 INR / Meter

Minimum Order Quantity : 500 Meters

Pattern Type : Solid Plain

Attributes : Other, Strong, Durable, Ecofriendly

Water Proof : Yes, Laminated for Water Resistance

Style : Other Style, Contemporary, Rustic

Shoes Laminated Canvas Fabric

Price 35 INR / Meter

Minimum Order Quantity : 500 Meters

Pattern Type : Laminated

Attributes : Other, Durable, Tear Resistant, Versatile, Smooth Finish

Water Proof : Yes, Water Resistant

Style : Other Style, Plain, Modern

Laminated Canvas

Price 35 INR / Meter

Minimum Order Quantity : 500 Meters

Pattern Type : Solid/Plain

Attributes : Other, Durable, Tear Resistant, Water Proof, UV Resistant

Water Proof : Yes

Style : Other Style, Laminated

Single Layer Strobel Cloth

Price 35 INR / Meter

Minimum Order Quantity : 500 Meters

Pattern Type : Solid

Attributes : Other, Single Layer Strobel Cloth

Water Proof : No

Style : Other Style, Woven

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS